VAP®: Membrane-assisted low-pressure infiltration

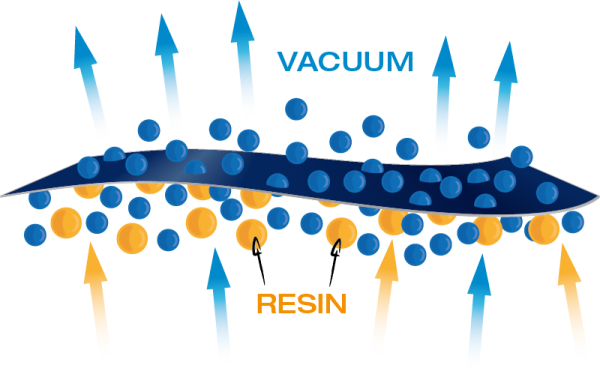

Air and reaction gases that are trapped during closed infusion processes can cause weaknesses in lightweight components. In conventional infusion processes, the entire assembly – subjected to low pressure – must be extensively flushed with the infusion medium until it can be safely assumed that there is no more trapped air and gas inside the component.

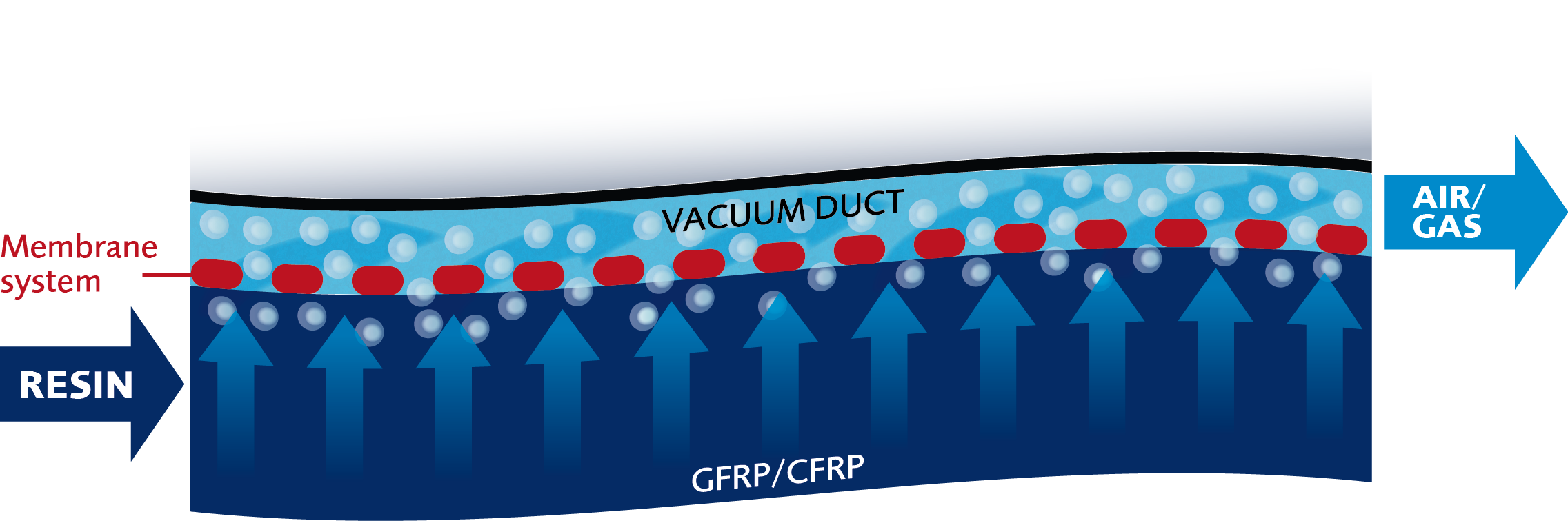

In the VAP®assembly, the flexible membrane system – which is permeable to gas but impermeable to the resin – is superficially contacted with the component. When the resin is infiltrated, it separates the matrix from the vacuum duct. With the aid of low-pressure, trapped air and gas can then escape through micro-permeability and are purged via the textile layer.

The vacuum acts uniformly, so trapped air and gas can be evacuated across the entire contact surface during and after infiltration.